Faux Wood vs Real Wood

At Elite Shutters

We are one of America’s premier wood shutter manufacturers and have always been innovators within our industry. In fact, we are significant contributors for many of the shutter designs seen within our industry today. Over the years, we’ve tried to keep an open mind about alternative materials offered for today’s shutter construction. However, we do feel that the plantation shutter industry was far less confusing for consumers before the onset of faux wood materials introduced in the mid to late 1990s. This section shares our 30+ years of experience (pros & cons) in working with various types of faux-wood materials for shutters.

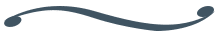

The enduring beauty of Elite’s authentic hardwood shutters (featured here) cannot be replaced by any faux material.

At Elite Shutters

We are one of America’s premier wood shutter manufacturers and have always been innovators within our industry. In fact, we are significant contributors for many of the shutter designs seen within our industry today. Over the years, we’ve tried to keep an open mind about alternative materials offered for today’s shutter construction. However, we do feel that the plantation shutter industry was far less confusing for consumers before the onset of faux wood materials introduced in the mid to late 1990s. This section shares our 30+ years of experience (pros & cons) in working with various types of faux-wood materials for shutters.

The enduring beauty of Elite’s authentic hardwood shutters (featured above) cannot be replaced by any faux material.

Are Composite Shutters

A Better Investment than Real Wood Shutters?

In a word, NO! We have removed these inferior interior shutters from MANY homes. Composite is a fancy way of saying MDF. In simplest terms, you would not accept that an MDF piece of furniture from a discount store would be as strong as a solid wood piece of furniture. Interior shutters are no different. Composite (MDF) is simply sawdust glued back together and wrapped in vinyl. Be careful not to get caught up in the fancy sales brochures or inflated promises made when promoting these products. We strongly encourage you to actually read the products written warranty (the fine print) in detail.

MDF

(Medium Density Fiber)

MDF explained: Faux composite interior shutters are also called hybrid, woodlore, and composite, along with some other trade names. All of these window coverings are made from MDF as the base material. MDF is basically sawdust mixed with glue and formed in the shape required. The coatings range from a vinyl wrap to a painted finish. Advantages are cost to manufacture and cost to the consumer. They deceivingly look very much like more expensive wood shutters.

Composite (MDF) shutters are only stable in smaller sizes and they can resist warping. The disadvantages are their inherent inability to stand up to water. They have a habit of swelling, and the finish peels when exposed to too much moisture. The material is brittle and can easily break under impact. The material is very heavy, and it will eventually sag under stress over a long period. Despite its many disadvantages, this material is rapidly becoming a major part of the window covering market due to its low cost and a general lack of consumer knowledge.

MDF

(Medium Density Fiber)

MDF explained: Faux composite interior shutters are also called hybrid, woodlore, and composite, along with some other trade names. All of these window coverings are made from MDF as the base material. MDF is basically sawdust mixed with glue and formed in the shape required. The coatings range from a vinyl wrap to a painted finish. Advantages are cost to manufacture and cost to the consumer. They deceivingly look very much like more expensive wood shutters.

Composite (MDF) shutters are only stable in smaller sizes and can resist warping. The disadvantages are their inherent inability to stand up to water. They have a habit of swelling, and the finish peels when exposed to too much moisture. The material is brittle and can easily break under impact. The material is very heavy, and it will eventually sag under stress over a long period. Despite its many disadvantages, this material is rapidly becoming a major part of the window covering market due to its low cost and a general lack of consumer knowledge.

Long term issues with Faux Woods

While many consumers of faux wood shutters may initially have a good experience, that experience all too often wanes over the years. The extruded color of faux material can fade, yellow, discolor, scratch, and even stain on certain occasions. In fact, most faux wood shutters now have to be painted with a finish coat to keep them from discoloration.

Today, most faux wood products are sold by franchise operators and big-box retailers. These companies often exist on volume selling by undercutting the wood prices to maintain a presence in the marketplace. Sadly, all too often their primary motivator is to achieve the highest profit margin, not by the legacy of their brand.

Long Term Issues with Faux Wood

While many consumers of faux wood shutters may initially have a good experience, that experience all too often wanes over the years. The extruded color of faux material can fade, yellow, discolor, scratch, and even stain on certain occasions. In fact, most faux wood shutters now have to be painted with a finish coat to keep them from discoloration.

Today, most faux wood products are sold by franchise operators and big-box retailers. These companies often exist on volume selling by undercutting the wood prices to maintain a presence in the marketplace. Sadly, all too often their primary motivator is to achieve the highest profit margin, not by the legacy of their brand.

Do Poly Shutters last longer than Wood Shutters?

Polypropylene comes in many forms, from hollow poly to aluminum reinforced poly and everything in between. A quality poly shutter can be helpful in a high humidity area such as a shower, but in most situations, a premium wood shutter will be stronger and last longer than a poly shutter. Poly shutters are extremely, heavy and over time, they tend to sag and “rack” in the window frame causing the shutter to drag. A quality-built wood shutter will not do either. Only low-quality wood shutters warp and “rack” in the window frame. In addition, poly shutters look and feel like plastic, and they have limited design options. Here at Elite, we have stayed committed to a premium wood shutter for its longevity, beauty and versatility.

Before

Before

After

After

Do Poly Shutters last longer than Wood Shutters?

Polypropylene comes in many forms, from hollow poly to aluminum reinforced poly and everything in between. A quality poly shutter can be helpful in a high humidity area such as a shower, but in most situations, a premium wood shutter will be stronger and last longer than a poly shutter. Poly shutters are extremely, heavy and over time, they tend to sag and “rack” in the window frame causing the shutter to drag. A quality-built wood shutter will not do either. Only low-quality wood shutters warp and “rack” in the window frame. In addition, poly shutters look and feel like plastic, and they have limited design options. Here at Elite, we have stayed committed to a premium wood shutter for its longevity, beauty and versatility.

Before

Before

After

After

Our Experience

Over the years, we have seen it all and experienced firsthand the outcome of some of these products. Our experience has found there are a few applications appropriate for a poly shutter. Some examples would be if a window needs to be shuttered inside the shower (yes, it happens!) or inside garages or attics. We put a custom color finish coat on our faux line to keep it from yellowing in the window. We only offer a solid polymer extruded shutter (never MDF). Poly is limited to a 10 year warranty as compared to the Lifetime Warranty offered on our wood shutters.The premium North American Hardwood we use for our plantation shutters is sourced from sustainable and responsibly managed forests and is finished with completely non-toxic finishes. Learn more about our wood shutters.

Our Experience

Over the years, we have seen it all and experienced firsthand the outcome of some of these products. Our experience has found there are a few applications appropriate for a poly shutter. Some examples would be if a window needs to be shuttered inside the shower (yes, it happens!) or inside garages or attics.. We put a custom color finish coat on our faux line to keep it from yellowing in the window. We only offer a solid polymer extruded shutter (never MDF). Poly is limited to a 10 year warranty as compared to the Lifetime Warranty offered on our wood shutters.The premium North American Hardwood we use for our plantation shutters is sourced from sustainable and responsibly managed forests and is finished with completely non-toxic finishes. Learn more about our wood shutters.

Most Quality Shutter Manufacturers

Prefer Real Wood Construction

Elites authentic American wood shutters are Heirloom quality, built to last a lifetime. If fact, we back our American Hardwood Shutters up with an exceptional lifetime warranty … see warranty

One way to tell if a faux wood shutter is an import is by the price. Because synthetic and engineered wood materials have to be created in a manufacturing process, formed, milled, cut, assembled and finished like a wood shutter, the cost is sometimes higher than wood. Most likely, the lower-cost faux products are not made in America. Many companies also import the components and assemble them in the USA. The foreign companies also hide under different company names that sound American.

All too often, consumers who buy faux wood products have no idea their products are from China, Mexico or other sources outside the USA. It pays to do your research and don’t be afraid to ask where the product is being sourced form. We do offer an American-made polymer shutter that will work well as an alternative to real wood for those rare instances where moisture may be of concern.

Most Quality Shutter Manufacturers

Prefer Real Wood Construction

Elites authentic American wood shutters are Heirloom quality, built to last a lifetime. If fact, we back our American Hardwood Shutters up with an exceptional lifetime warranty … see warranty

One way to tell if a faux wood shutter is an import is by the price. Because synthetic and engineered wood materials have to be created in a manufacturing process, formed, milled, cut, assembled and finished like a wood shutter, the cost is sometimes higher than wood. Most likely, the lower-cost faux products are not made in America. Many companies also import the components and assemble them in the USA. The foreign companies also hide under different company names that sound American.

All too often, consumers who buy faux wood products have no idea their products are from China, Mexico or other sources outside the USA. It pays to do your research and don’t be afraid to ask where the product is being sourced form. We do offer an American-made polymer shutter that will work well as an alternative to real wood for those rare instances where moisture may be of concern.

Ready to Speak with a Shutter Expert?

Contact Us Today! Elite Shutters is an industry leader for true authentic wooden plantation shutters.

Or, call us directly at 877-793-1726.

Awards & Certificates

Winners of the Best of Houzz 2014 – 2024 – Customer Service. Rated at the highest level for customer service by Houzz eight times from 2014 – 2024.

Follow Us